Power Semiconductor Test Equipment

As a worldwide supplier of power semiconductor testing equipment, ITC has a range of tester products to address all production test and characterization needs. These systems include the industry standard series of Unclamped Inductive Load Test Systems.

![]()

Integrated Technology Corporation has been serving the needs of our customers since 1975.

We provide solutions for metrology and testing equipment in many areas:

- Test, analysis, and repair of IC probe cards

- Innovative metrology and inspection solutions

- Solutions for dynamic testing of power semiconductors

The Ideal Probe Card Analyzers

The ITC line of Probilt, probe card analyzers provide fast, accurate and repeatable test data for all types of probe card technologies. Simple user definable vision parameters allow even the newest and most complex probe tips to be captured and accurately measured.

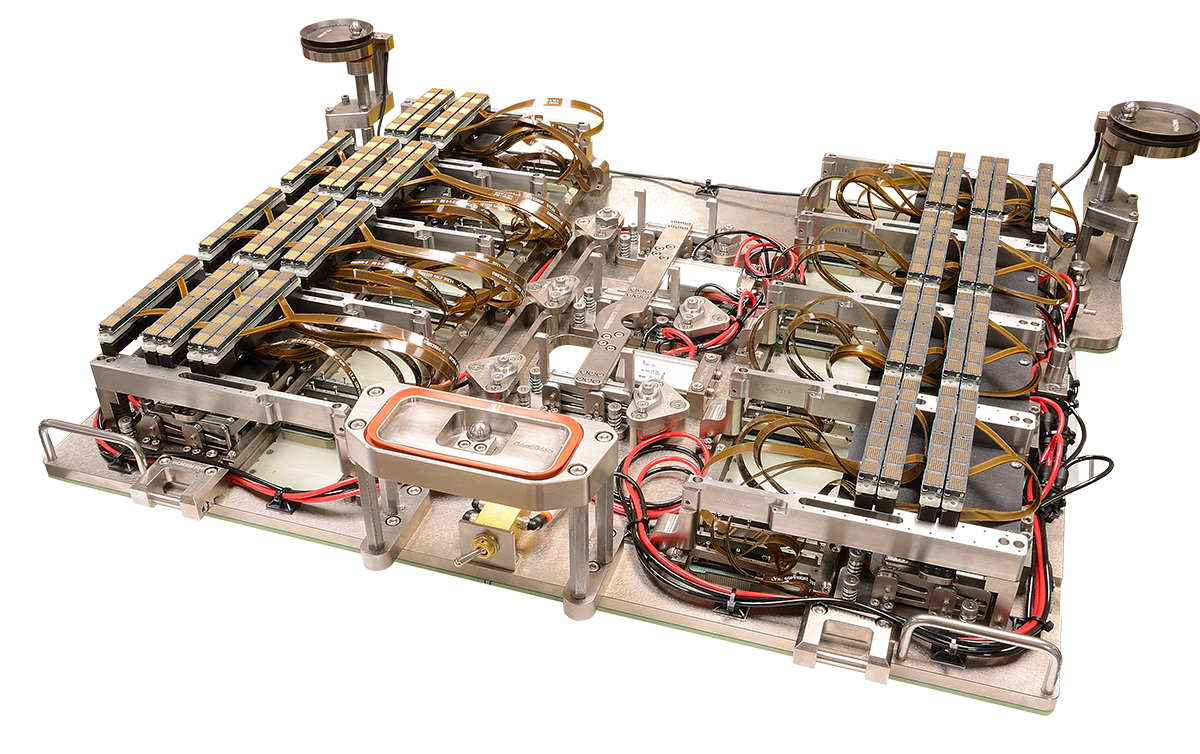

High Current & High Voltage UIL Test Solutions

The rapid innovations and developments within the semiconductor industry in general have also been very apparent within the power device sector of the industry. The move to Silicon Carbide (SiC) power devices has resulted in higher breakdown voltages for discrete devices which in turn requires the UIL test solution to have a higher voltage capability.

ITC, as the world leader in UIL test solutions, has developed 4000V/200A UIL test systems on both its 55 and 75 series testers. The ITC55100C-2HVN and the ITC75100-2HVN are both N-channel only systems with the 4000V/200A capability.

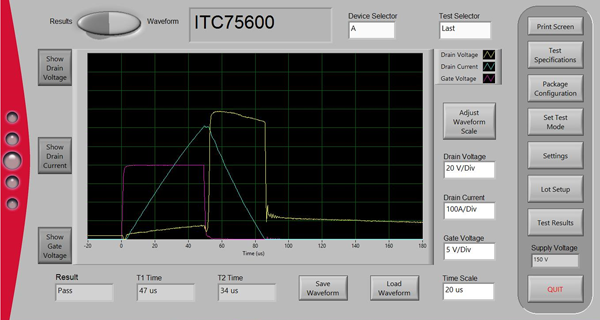

Product Highlight

ITC55100C Crowbar (Patent Pending)

This option for the ITC55100C UIL tester provides a parallel energy path that in the event of an avalanche failure takes the energy away from the device under test. In a wafer probe application it provides protection for the probe card and the device under test, stops debris scatter across the wafer and prevents the avalanche failure from impacting adjacent die.

Customized Motherboards

ITC currently manufactures over 100 different motherboard types, including interfaces to all major brands and types of testers. Additionally, ITC has the ability to quickly design and manufacture motherboards for any new tester interface including custom probe cards. Our Motherboards are built to reproduce or respond to actual factory probe card testing conditions by emulating Tester Mechanical Conditions with the same forces on Probe Card using the same connector control methods. Also, our motherboards emulate wafer prober card holding conditions using the same forces on Probe Card and maintaining the same reference surface.